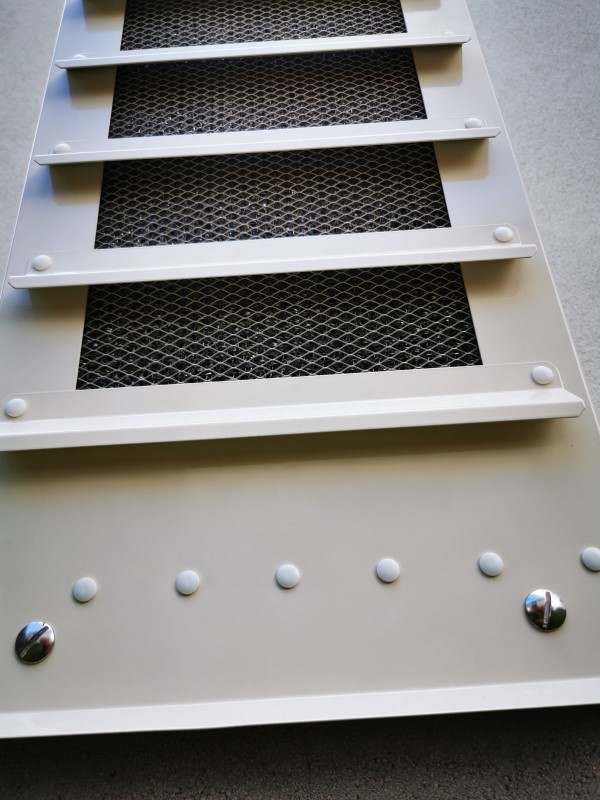

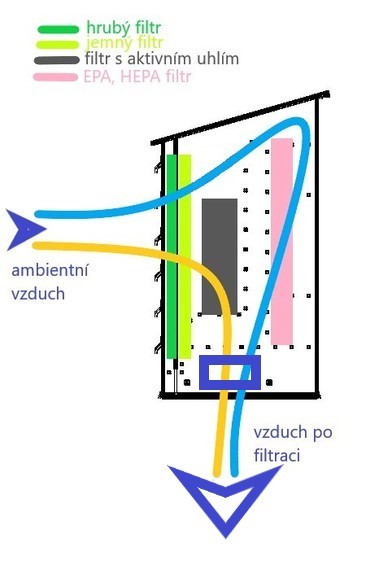

The filter unit draws in outside air through a field of protective blinds:

- in the basic configuration (I.+II.), the air passes through a coarse filter and fine filter

- in the configuration protecting against formation of vapors, odors, chemical substances etc. (III.), the air passes through the coarse, fine filter and the activated carbon cartridge assembly

- In the configuration preventing the ingress of microparticles into the ventilated object (IV.), the air passes through a coarse, fine, HEPA filter

The clean air is further sucked in or forced out into the suction pipe of the ventilation system or the ground register of the family house.

--------------

The standard composition of filters is chosen so as to prevent or minimize the penetration of health-threatening or unpleasant substances into family houses and similar-sized objects. Dust, fly ash, odors, pollen and allergens, chemical and biological substances that can be encountered or cannot be ruled out in densely populated agglomerations, in areas near chemical plants, biological laboratories or power plants, etc. were taken into account

--------------

- coarse filtration - only coarse filter mounting, filter KS MA fitted as standard

- fine filtration - filter KS MPP fitted as standard

The coarse filter and the medium filtration filter form the basic configuration of the filter unit.

The installation of these filters is justified in all cases. This composition of the filters will limit the ingress of impurities normally contained in the air into the ventilated building as well as serve as a protection against contamination of the ventilation systems.

In the case higher quality of normal-continuous filtration in demand - ie where the M6 class filter proves to be insufficient, it can be replaced by a F7-F9 class filter.

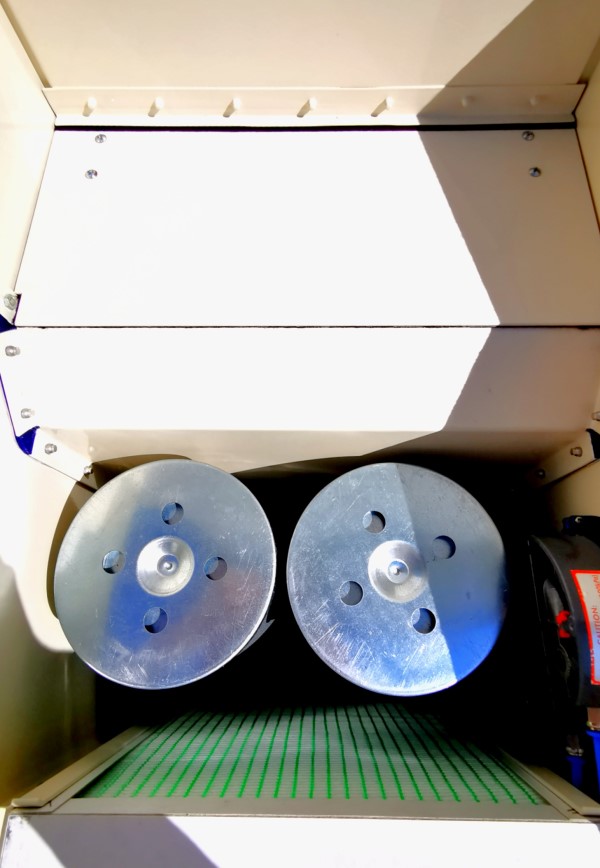

- absorption filtration with active carbon - adsorption filter with active carbon, eg. KS KOPA

Non-impregnated active carbon has pore-like structure and large inner surface, which allows it to adsorb a wide range of substances.

In the case of an impregnated active substance, a chemical reaction takes place between the harmful substance and the impregnant with the aim of chemisorption of the harmful substance or its neutralization.

The installation of active carbon filter cartridges should be justified by the actual presence of one or another pollutant in the air.

- HEPA filtration - eg. KS Bestfil

The large area of the filter medium at the absolute filter allows for its economical either temporary or permanent use.

On the external right side of the casing is located a manometer monitoring the difference between the pressure at the air inlet and outlet of the filter unit. The selected configuration and the value obtained from the manometer help to determine whether the filters are in need of regeneration or replacement.

The ventilation system of a family house should compensate the pressure loss of the filter unit and ensure that air pressure is similar or slightly higher than the atmospheric pressure.

If the ventilation system is not capable of the actions described above, then the filter unit can be joined by additional extension.

Regarding safety, the unit is protected against accidental or unintentional restriction of its function. If the filter unit is installed in a publicly accessible place, it can be fitted with an additional safety extension.

Technical data, dimensions:

- size (w*d*h): 405*534*925 mm

- material: lacquered aluminum, thickness 1 mm, construction 2 mm

- colour: white pearl RAL 1013

- connecting pipe DN200

- pressure drop without filters 8Pa

Filter slot size:

- coarse filter slot 600*290*22 mm

- fine filter slot 600*290*35 mm

- slot for HEPA filter 611*308*70-75 mm

- slot for mounting two cartridges with activated carbon D145*450 mm

Requirements and classes of filtration.

* pressure losses counted for the air volume fow of 300m3/hour

* slots for the filters are of common size, they can be fitted with filter of quality you request

* final pressure drop - the pressure drop of a clogged filter - is approximately twice the initial pressure drop